We specialize in manufacturing and commercializing microcapsules.

Click here for inquiries in English.

MR sheet (magnetic powder capsule sheet) VISUAL MAGNETIC SHEET (V-sheet) Encapsulated Liquid Crystals (ELC)

MR sheet (magnetic powder capsule sheet)

Outline

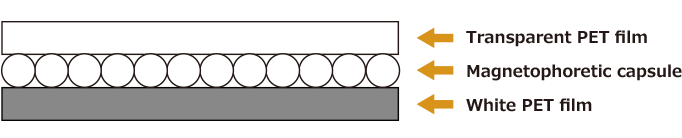

The MR sheet is a magnetophoretic sheet developed by applying our microcapsule technology, and its structure is as follows.

Iron oxide that displays black in the fluid medium oil, titanium dioxide that displays white when erased, and dispersion medium liquid with some additives are dispersed and encapsulated with a particle size of about 200 to 300 μm.

Mechanism

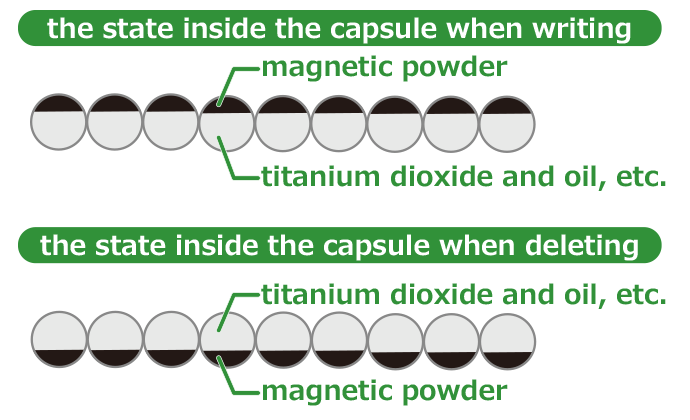

When writing with a magnetic pen, iron oxide gathers at the top of the capsule, resulting in a black display. When an erasing magnet is applied to the back of the sheet, iron oxide gathers at the bottom of the capsule and turns white because the top and bottom are replaced with titanium dioxide (See below).

Features

- Product life is semi-permanent.

Since writing and erasing are magnetically done, so it can be used semi-permanently and repeatedly. - Pollution-free and cleanliness

It is completely clean because it doesn’t require traditional inks which the erasable text becomes a

dry solid powder and flies around the room. - Favorable economics

Ink (auxiliary tools such as toner, felt pens, erasing pads, etc.) are not required at all. - Very light touch writing

Magnetic writing does not require a stronger writing pressure. - The characters do not disappear with touching

Even if a hand or a finger touches the writing surface, the characters do not disappear.

Patent

*USA 5057363

*Europa 0436262

See more details (Japanese only)

MR sheet (magnetic powder capsule sheet) VISUAL MAGNETIC SHEET (V-sheet) Encapsulated Liquid Crystals (ELC)

VISUAL MAGNETIC SHEET (V-sheet)

Structure

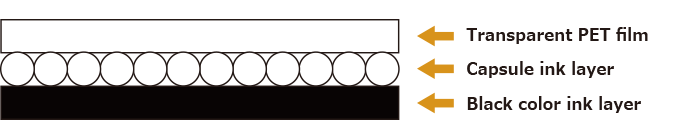

V-sheet is coated on the PET film with magnetic- migration capsule of a diameter 60 ~ 80 micron containing flattening (scaly) iron particles and pigment dye (if necessary) dispersed in oil.

Mechanism

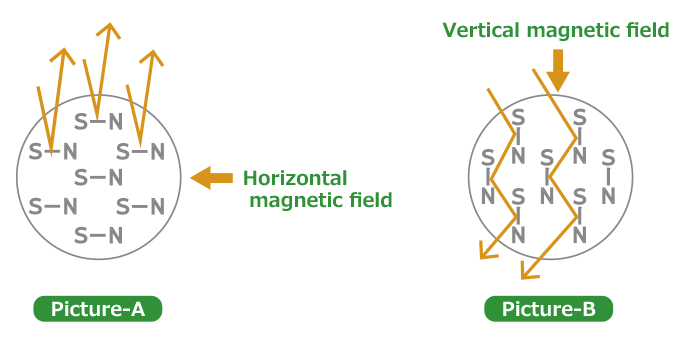

Pictures below (Picture-A & Picture-B, showing magnetic pole or pole pattern) are created by the contrast between light and dark. The contrast in Pictures is created by absorption (or reflection) of light caused by movement of flattening iron particles in microcapsule when a horizontal (or vertical) magnetic field is applied to the magnetic sheet.

When a horizontal magnetic field is applied to the magnetic sheet, flattening iron particles in microcapsule are oriented to the horizontal direction. (See Picture-A)

This means sheet surface becomes lighten due to reflection of light.

When a vertical magnetic field is applied to the magnetic sheet, meanwhile, flattening iron particles in microcapsule are oriented to the vertical direction. (See Picture-B)

This situation cause a darkened appearance to the sheet surface due to absorption of light.

Main Applications / Products

It is used in various fields as a sheet that can magnetically display information.

- Magnet viewer (magnetized view)

- Erasing marker for magnetic recording eraser

- Magnetic Rewrite Card

See more details (Japanese only)

MR sheet (magnetic powder capsule sheet) VISUAL MAGNETIC SHEET (V-sheet) Encapsulated Liquid Crystals (ELC)

Encapsulated Liquid Crystals (ELC)

Mechanism

Cholesteric liquid crystals, when formulated properly, respond to changes in temperature by sequentially passing through the complete visual spectrum, i.e., red-green-blue-violet. This color phenomenon is reversible.

Colors scattered by liquid crystals represent only a fraction of the incident light. The remaining portion of the incident light is transmitted by liquid crystals. As absorptive black background is, therefore, needed to prevent reflection of the transmitted light.

Cholesteric liquid crystals often present a number of problems because they are viscous liquids.

The problems associated with handling and use of these materials are:

- Flow tendency of liquid crystals can cause variations in applied film thickness, which may result in non-reproducible thermal patterns.

- Direct exposure of liquid crystals to the adverse environmental effects of solvent vapors, oils, dirt and ultraviolet light can cause variations in their sensitivity.

- Liquid crystals, responding in different temperature ranges, can not easily be used simultaneously or homogeneously at a given sight.

ELC is a new concept in the field of thermally sensitive compounds. Through use of ELC, a new vista of applications heretofore not considered, become feasible.

These tiny packages, normally 5 to 15 microns in diameter, offer numerous major advantages.

Micro-encapsulation

- Convert the liquid crystals to a pseudo-solid, providing ease of handling, application and use.

- Provides longer shelf-life by minimizing surface contamination and giving protection from ultraviolet light.

- Offers reversibility in thermal operation with no indication of fatigue after one million cycles.

- Permits simultaneous use of more than one liquid crystals, responding in different temperature ranges at a given site.

- Allow permanent geometrical designs of liquid crystals to be deposited on film, paper, and other substrates.

Main Applications / Products

The color changes reversibly with temperature, so the applications are diverse.